Scaling and Automation; 6 Figure 3D Printing Business From Home

If I did it with no prior 3D design experience, you probably can too!

If I did it with no prior 3D design experience, you probably can too!

Imagine yourself having a 3–4 hour workday, designing and making useful products that people love from the comfort of your own home, taking time off when you need without having to ask for permission, and earning enough to have a decent living.

>>>The video version of this story is available at the end.<<<

Identifying a Profitable Niche

As I look back at my journey, I realize that one of the most significant steps for others will be identifying a profitable niche. My niche fell into my lap; I was not a 3D print hobbyist looking for a product to sell. I had a product I wanted to make, we needed adequate production tools that were hard to source, so I started 3D printing my own production tools, others wanted to buy them, and the rest is history.

Many aspiring entrepreneurs often overlook the importance of niche selection, but from my experience, this fundamental choice can set the stage for your entire business. In this section, I want to share how you can find that niche that not only resonates with you but also meets an essential demand in the market.

While I definitely stumbled into a “right place / right time” situation, with some planning and research, I truly believe anyone can enter a niche market with the right idea and delivery.

What are you an authority on?

Choosing a niche isn’t just about picking a trendy topic or a common hobby. It’s about understanding the needs and challenges of a specific group of people. When I started my 3D printing business, I quickly learned that the saying,

“Necessity is the mother of invention”

My venture into the world of 3D printing was birthed from a personal need that wasn’t being adequately met in MY marketplace.

Ideally, this solution you are providing is related to a passion, hobby, or a profession that you are already connected to. Being an authority beyond the printed part is one of the ingredients involved in why my business has remained successful over 7 years. I also offer knowledge and training relating to the very esoteric process that my tools were made to assist with.

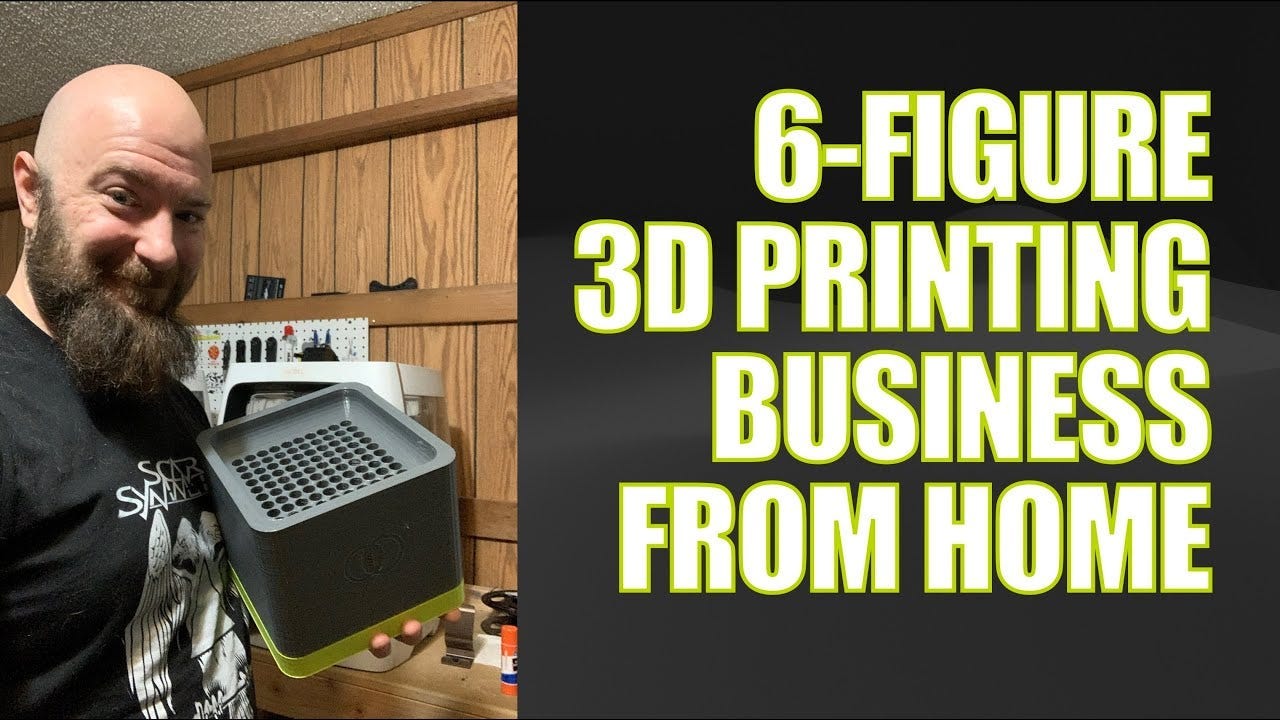

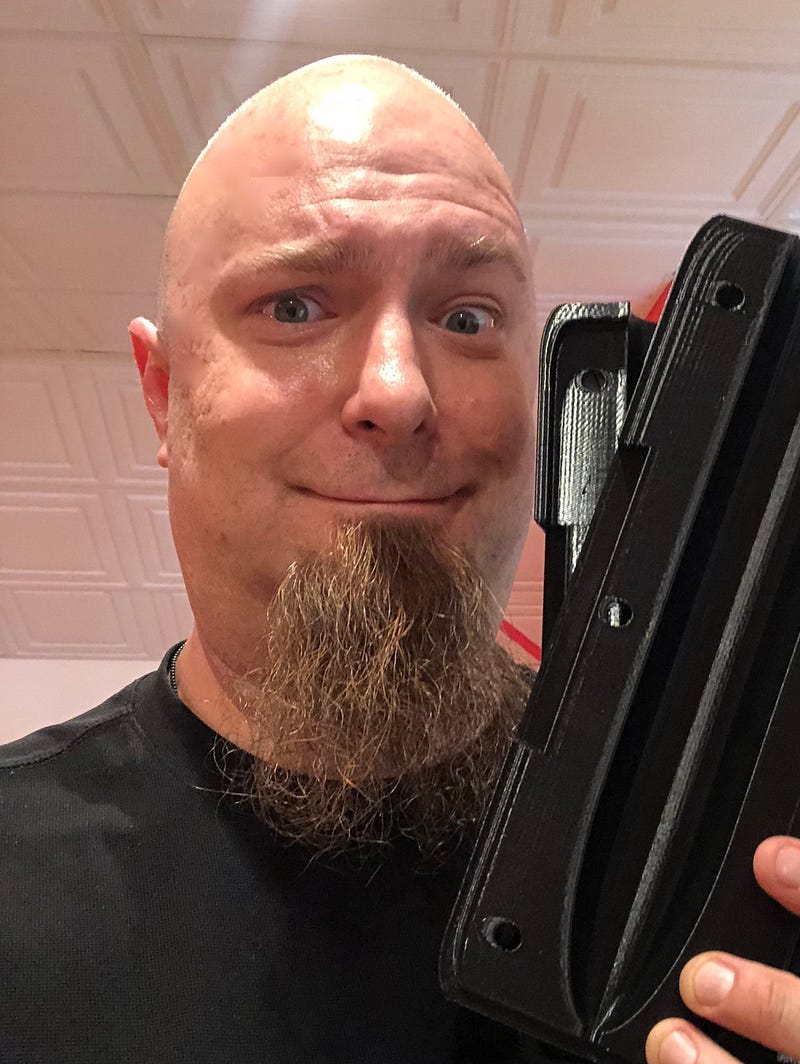

In 2016, I recognized a growing demand for cigar molds within a market niche I was already involved in. It was a niche that was emerging and expanding, with few resources available for production tools. It was this observation that led me to develop Cannagar Tools, a brand focused on creating specialized and custom molds for cannabis cigars. By addressing this need, and being very intimate with the entire process for which my tools were being used, I was able to build a six-figure business at home.

The business:

Cannagar Tools Herbal Craft Molds & Accessories

Tools for making form-factor perfect cannagars!cannagartools.com

Leverage Your Passions and Hobbies

While my story in the cannabis industry is one example, many other successful niches exist which may prove perfect for 3D printed parts.

For instance, custom automotive parts cater to a dedicated segment of car enthusiasts who often seek out hard-to-find components.

Creating replicas of original equipment manufacturer (OEM) parts that are both difficult to locate and expensive, using the best plastics and printers that can create strong smooth parts, such as the Qidi X Max Series, might be an excellent angle into finding profitable products.

You can choose from material like Carbon Fiber, Polycarbonate, and other materials that are both durable, sturdy, and have a beautiful professional surface texture.

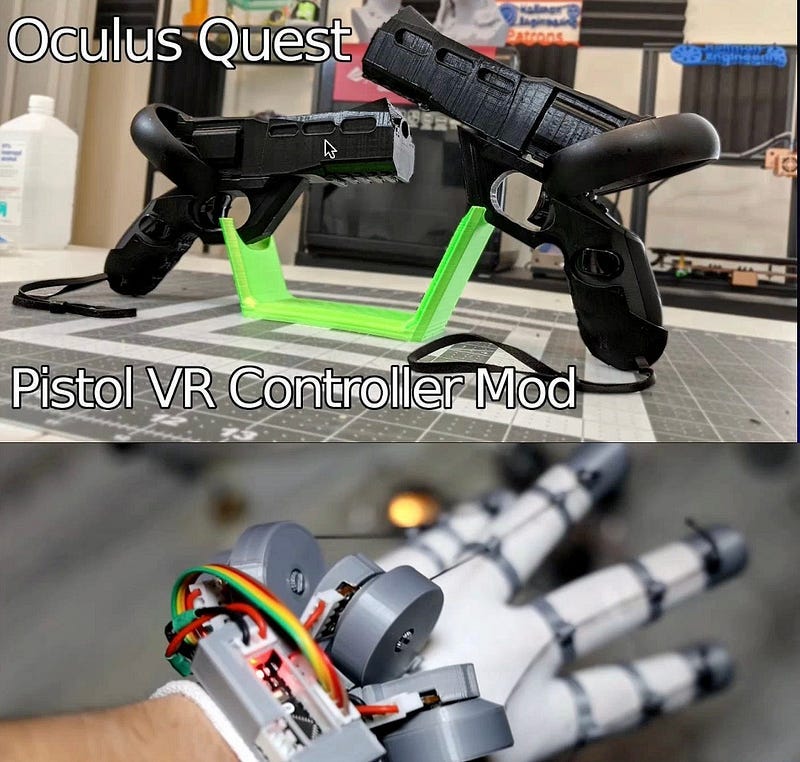

There are also options like designing accessories for video games or virtual reality headsets — these are areas brimming with potential!

The secret of finding a truly workable niche lies in your personal passions and areas of expertise.

What Revs Your Engine?

Reflect on your hobbies and interests.

What do you enjoy doing?

What problems do you encounter in those areas?

Could any of those problems use a 3D printed solution?

By thinking about these questions, you could potentially discover product ideas that resonate with you.

There’s an extraordinary connection when you create a product that you are genuinely passionate about because it not only makes the work enjoyable but positions you as an authority in that niche.

Conducting Research to Validate Your Niche

Before diving headfirst into a business, validate your idea.

Is there truly a demand for the item you want to make?

Are there others in the space already successful at what you are doing?

How can you improve on what they are doing?

Analyze online forums relevant to your niche. Often, you can uncover insights that can shape your product development so you can find the angle to improve on something and find your edge.

Are there common complaints from users?

Features they wish were available, but are not?

These insights can guide you in optimizing your focus and isolating the product you will select/develop.

For instance, in my case, existing tools for cannabis cigar molds were available in limited shapes and sizes, often at steep prices. This limitation represented a gap my 3D printing service could uniquely fulfill. If you target a niche where the player landscape is sparse, you can accelerate your business growth, especially when you address the pain points of your customers.

Ideological Fuel for Innovation

Beliefs and convictions can also guide you to uncover profound needs in various sectors. Perhaps you’re an advocate for eco-friendly products. This passion could lead you to develop sustainable solutions through 3D printing technology and to use plant based plastics and other more compostable / degradable product options.

From day one, I have been using a plant-derived plastic called PLA (the most common low priced 3D print plastic), and I also recycle all the waste from my own print lab, and offer free recycling to any customer who wants to recycle their used products. When it was available, I was making my products from 3D printable hemp based PLA, which sold well and my customers loved it.

Even if your interests lie elsewhere, don’t hesitate to think broadly about how 3D printing could enhance those areas.

Whether it’s manufacturing custom orthotics for pets, creating hobbyist niche products like Dungeons and Dragons props and figurines, or prototyping innovative designs, the sky is the limit.

Embrace Continuous Learning

Once you find your niche, it’s crucial to stay informed and adaptable. Trends and needs can shift swiftly. Make it a habit to follow industry news, connect with fellow entrepreneurs, join forums, or attend trade shows. This ongoing education will keep you engaged with your audience and monitor their evolving needs.

In my case, once the initial demand for cannabis cigar molds surged, I made it my mission to innovate further. By actively seeking feedback from customers and exploring emerging trends, I was able to spot the next opportunity. This allowed me to expand my product range into pre roll loaders and rolling platforms, and branded accessories that assist the process. It also motivated me to offer custom designs and other options that are usually cost prohibitive for most companies using manufacturing methods like injection molding, or CNC.

Many people not only wanted the sizes and shapes that I offered, but they were thrilled that I could help them make whatever their imagination conjured up.

I have made some pretty wild cigar molds, like this 12 inch 100 gauge torpedo mold :

Putting It All Together

To identify your niche, it’s all about making connections between your interests, market demands, and your ability to innovate. Always seek to fulfill a need, and your endeavors will likely lead to unexpected and rewarding outcomes.

With the right approach, you’ll not only enjoy the journey but also create a thriving business along the way.

Implementing A Time-Saving Workflow

Optimizing Your Workday

For my first 6 months, my daily routine involved a chaotic scramble of tasks. However, after streamlining everything piece by piece, I was able to create a structured timeline that led to greater overall efficiency and a part time work schedule with a full time income. My day now started with a coffee (essential for motivation, right?) and planning how to tackle the tasks at hand.

Printer Prep: I allocated the first hour of my day to remove yesterday’s finished prints, then prep my printers for their next print jobs and get them started

The parts I am printing take over 12 hours to produce, meaning once they have started, I have no more interaction with the printers themselves until the next day.

Order Fulfillment. I then focused on processing orders that were ready to go out, boxing them, printing labels, then putting them on my porch for the postman.

Regular Maintenance. Instead of waiting for printers to need service, incorporating a quarterly maintenance schedule helped me avoid unexpected issues.

Utilize high-quality components. Don’t cheap out on replacement parts. This significantly reduces wear and prevents you from having to throw away parts.

Examples of recommended components:

Tungsten nozzles. Minor cost that is a game-changing upgrade. I’ve been using Dyze Design Tungsten nozzles for 6 years, never had to change them, saving me $1000’s of dollars in nozzle replacements and wasted prints. Brass Nozzles wear down, which causes the dimensions of a part to be inconsistent. You have to change them constantly. Other nozzles have their own flaws. Tungsten, my parts have been consistent for 6 years without changing nozzles.

Tungsten Carbide 3D Printer MK8 Extruder Nozzle, High Temperature Printing, Super Wear Resistant…

About MK8 Extruder Tungsten Nozzle: 1. It has highest hardness and high temperature resistance in the market at same…amzn.to

BuildTak spatula. A special 90 degree ultra thin spatula made removing prints much easier without damaging the prints, or printer beds.

BuildTak Spatula

Make the removal process easy! This tool has been developed specifically for the FFF 3D printing world. It features a…www.buildtak.com

When I operated my small print lab with twelve machines, I quickly realized that neglecting maintenance leads to frustrating breakdowns and repairs happening according to Murphy’s law. To mitigate that, I set up a quarterly maintenance schedule, which typically required around eight hours. I systematically checked each printer for wear and tear, cleaned the nozzles, and ensured all components were in working order.

One full day of maintenance every 90 days saved me lost time and multiple weeks of random equipment being down.

As an added tip, make a checklist that you can refer to during each maintenance session. It ensures that nothing is overlooked. I found that documenting my maintenance activities helped me identify patterns and anticipate future repairs, keeping my workflow smooth.

My Automation Adventure Begins

Many might stop here, happy that they have a thriving business in their garage. Certainly, that is an option. However, in starting my own business, even though I could technically take time off when I wanted without having to ask permission from anyone, I still hadn’t solved a problem of my own : I really wanted time and location freedom.

Many might stop here, happy that they have a thriving business in their garage. Certainly, that is an option. However, in starting my own business, even though I could technically take time off when I wanted without having to ask permission from anyone, I still hadn’t solved a problem of my own : I really wanted time and location freedom.

By the time 2020 rolled around, I had managed to scale my sales to over six figures. Yet, when the pandemic hit, my revenue took a nosedive to around 90k, and I was also wanting to get into the ourdoors with a woman I had met who was an avid hiker. Not being able to take the time off that I wanted during a time when revenue was low because I needed to chase sales like crazy and couldn’t break away — was the wake-up call that propelled into automation.

By the time 2020 rolled around, I had managed to scale my sales to over six figures. Yet, when the pandemic hit, my revenue took a nosedive to around 90k, and I was also wanting to get into the ourdoors with a woman I had met who was an avid hiker. Not being able to take the time off that I wanted during a time when revenue was low because I needed to chase sales like crazy and couldn’t break away — was the wake-up call that propelled into automation.

Finding the Right Automation Tools

Imagine this: waking up early to finish prints, prep the next days print jobs, and handling shipping logistics — all while managing orders and customers from clients. That routine can get overwhelming for one person at times, especially when you are the only one running it, and you have to get product out.

I decided to outsource my printing, and only focus on operations and custom jobs at home.

It took a while, almost a year, to find a printing partner willing to take on my orders and also not charge nearly as much as most 3D printing services.

Unfortunately, for a product of my size and weight, and the average market price I was competing with, I couldn’t use super convenient On-Demand manufacturing services like Shapeways or Xometry.

Custom Online 3D Printing Service

Xometry's online 3D printing service is a leader in custom additive manufacturing. With free shipping on all U.S…www.xometry.com

If you have a product that is viable to produce this way, then you already have the battle won. These services make it easy as pie when you have a product that lines up with price/production/method.

I didn’t have a product where mass production made sense, and my size and weight just weren’t feasible to go to these manufacturing services. I had to find a guy who also ran his own print production who wanted to take on more and scale.

When I finally found a printing partner, I immediately needed a way to automate the fulfillment process so I would not have to manually submit every order to them, and I was investigating everything from email automation, to integrating our websites / ecom systems with zapier.

Outsourcing Made Simple, KISS — Keep It Simple, Stupid

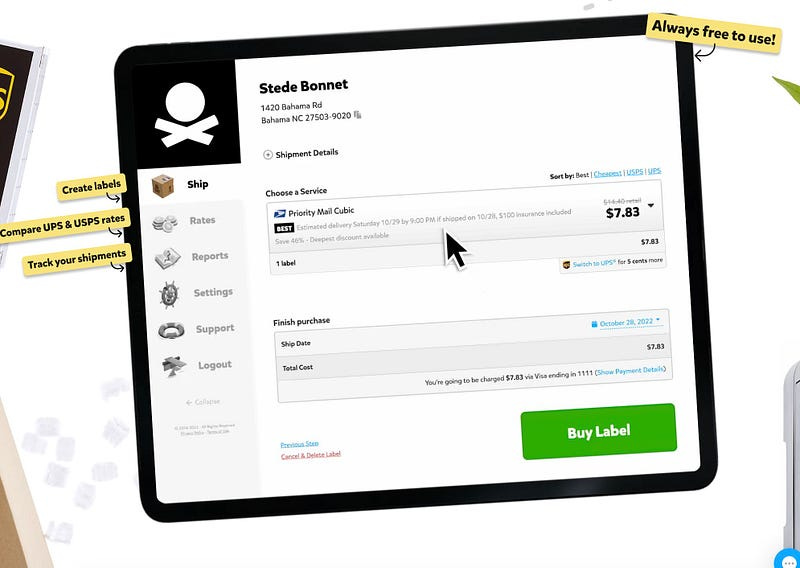

Then I remembered Pirate Ship, a free shipping software that had become the backbone of my home shipping process. It is a free service with no monthly charge that gives anyone access to the same rates as ShipStation, Shipping Easy, etc.

Pirateship was an unlikely but totally workable solution here. My partner signed up for Pirateship, at no cost to them, and I had installed the plugin on my website which was pointed to their Pirateship account, facilitating smooth order visibility and shipping management.

Order comes in, I collect payment.

They receive notice and see the shipment in their Pirateship account, including the full product list, and prices.

They print the order, and pack / ship.

At the end of the week, we settle up and I pay for their services and shipping cost, keeping the profit.

My Chatbots

I created my first chatbot in 2020 to handle customer support while I was hiking. This was a manually-created conversational flow bubble-chart style chatbot, and it took almost 2 months to build, another 4 months to test and deploy, and constant corrections to dead ends found in conversations until the final version was more or less capable of not pissing off my customers.

I am glad that was the only chatbot I ever built bubble by bubble. ChatGPT was born in 2023, and now it only takes about 3 days to train and deploy a new ecommerce chatbot, or a chatbot for almost any purpose really.

I have three of them running my websites now, one on each website. Each specializing in the content for that particular website.

The end result?

I am finally able to spend only about 2–4 hours a week on my primary business, focusing primarily on custom designs, and fine tuning marketing campaigns, rather than production and shipping.

Automation Summary:

I automated my 3D Printing business with only two tools.

Pirate Ship: Free shipping software, used for outsourcing workflow in this case.

Orimon AI: A GPT powered chatbot that handles 99% of customer interaction and pre-sales questions.

Achieving Work-Life Balance

The tasty chocolate nugget at the center of the automation tootsie-pop will be found in it’s ability to take over repetitive tasks for individuals and empower them to scale businesses in ways that were previously impossible. I can now efficiently manage my primary business in just a few hours, which frees up time for me to focus on building other income streams, personal interests and family needs.

The flip-side of automation stealing our jobs is….

It can empower an individuals to launch businesses that would have previously required reating a company, but can now be managed by one person, in less than part-time hours.

Through automation I learned that I could actually create a solid work-life balance that most entrepreneurs dream of.

I wouldn’t call it work life balance though.

I am HEAVILY tilted. There is no balance.

I am severely imbalanced on the Life side of things.

Just as I intended.

Realizing the Financial Benefits of Automation

When I made the commitment to automate my processes, I discovered unforeseen financial benefits that practically transformed my business model. Automation not only reduced my workload, but was actually working out for customers too.

I was terribly apprehensive of deploying a chatbot, but it has turned out to be ok. Everything didn’t blow up.

Employees would make mistakes too, just like ChatGPT 3.5 did, but now, 4o is the closest thing to a human employee I have ever had.

An employee who cost me $59, one time, lifetime license, because that is how I roll.

Learning from Automation

When I decided to automate my processes, the change was transformative. Automation allowed me to streamline order fulfillment and significantly reduce the time commitment required for custom jobs. I embraced tools like shipping software that integrated with my printer partners, enabling order visibility and automated shipping without tedious manual efforts.

As a case in point, utilizing a platform like Pirate Ship made a remarkable difference in my workflow. Now, rather than manually processing every shipping label, I could focus more on creative aspects, like product design and customer relations. Automation is key in today’s businesses; it frees up valuable time you can redirect toward growth and innovation.

Financial Benefits of Regular Maintenance

Investing time and effort into routine maintenance can result in significant cost savings. Failing to address wear and tear on your printers can lead to exorbitant repair bills or even the need to replace expensive equipment altogether. In my experience, a proactive maintenance approach mitigated these risks immensely:

Reduced Breakdowns: By regularly maintaining my printers, I experienced fewer unexpected breakdowns, which in turn meant my machines were often operational.

Improved Longevity: Each machine I maintained lasted longer than anticipated, and I didn’t have to worry about investing in replacements too frequently.

“Maintenance is key to ensuring longevity in your machines.” — Christopher Morton

This quote resonates deeply with me, as it encapsulates the essence of what I have learned throughout my journey in this industry. Frequent maintenance is not a burden but an investment that pays dividends in operational efficiency and productivity over time.

In essence, cultivating an efficient operation and establishing a robust maintenance schedule has been pivotal to my success in the 3D printing business. The systems I’ve implemented led to optimized processes, allowing me to focus on creativity and business growth. I encourage you to take these insights, apply them to your situation, and witness the difference that a structured approach can make.

Conclusion: The Journey Continues

Reflecting on my entrepreneurial journey, I can attest that building a business from scratch is a path filled with numerous ups and downs, challenges and successes. I began with a home-based 3D printing business in 2017, and my experiences have shaped not only my business acumen but also my character. From toiling through late nights to streamline operations, every moment has taught me something valuable.

As I encourage you to explore your passions for potential products, I recall the moment I decided to dive into the cannabis industry. Rather than being solely motivated by profit, my primary aim was to solve a need I recognized in the market. This highlights my first point: the journey becomes significantly more rewarding when it intertwines with something you genuinely care about. Remember, the most successful entrepreneurs base their ventures on passion and the desire to meet an unmet need.

It’s crucial to identify a specific market niche. The saying, “necessity is the mother of invention,” became my guiding principle. Whether it’s creating OEM parts for classic cars or custom accessories for gaming devices, ensuring that your product serves a particular need can distinguish you in a saturated market. I started with cigar molds specifically designed for cannabis — and I believe anyone can find that competitive edge by addressing a unique demand within their area of interest.

As I reflect on challenges encountered throughout this journey, I realize that every setback has shaped me into a stronger entrepreneur. Adapting to the sudden changes brought on by COVID-19 in 2020 pushed me to rethink my entire business model. Instead of allowing fear to dictate my next steps, I embraced change and sought automation as a solution. Automating my processes not only reduced my weekly work hours but also optimized my workflow significantly.

In the world of entrepreneurship, sharing experiences is vital. Embracing community support — whether through local business organizations, online forums, or networking events — has been invaluable for me. Building relationships with like-minded individuals has enriched my knowledge and provided moral support during rough patches. As I’ve often said, “No entrepreneur is an island.” Whether you’re starting off or are a seasoned business owner, don’t hesitate to reach out for guidance. We’re all in this together.

Staying adaptable and open-minded has been a cornerstone in my journey. I learned that flexibility can lead to unexpected opportunities. For instance, transitioning from Morphe to Fusion 360 required a shift in mindset. Initially, the learning curve was steep and frustrating, but rather than resisting change, I embraced it. Today, I’m exploring additional software like Shapr3D, continuously refining my skills while remaining committed to the growth of my business.

“Every challenge is an opportunity in disguise.” — Unknown

The essence of the entrepreneurial spirit lies in resilience. Think of the countless entrepreneurs who faced adversity before achieving success. For instance, the COVID-19 pandemic forced many businesses to pivot or re-evaluate their operations. Consequently, it can be beneficial to monitor ongoing trends in your chosen niche. By staying informed, you can adapt your products and strategies accordingly.

Additionally, collaborating with others has proven to be a catalyst for creativity. Group brainstorming sessions or development partnerships can lead to innovations you’d never consider alone. Even sharing frustration can become a source of motivation; fellow entrepreneurs can provide insights based on similar challenges they have faced.

Finally, as I continue down this path in my business, I reflect on how I initiated my 3D printing venture from home. What began as a journey into an uncharted industry turned into a significant source of income and creativity. I hope my experiences inspire you to take that leap of faith into your entrepreneurial journey. By anchoring your business in passion, engaging with community support, and maintaining an adaptable mindset, you’ll set yourself up for success.

In conclusion, your business journey is unique, and it’s normal to encounter hurdles along the way. Each step — whether forward or backward — contributes to your growth. So, as you embark on this fulfilling endeavor, keep in mind the importance of adaptability, community, and most importantly, passion. Your business is a reflection of your values and aspirations, a testament to what you believe in and what you wish to provide.

So go ahead, take the first step into your journey, and remember that the adventure is just beginning!

Disclaimer : this story was made by loading my YouTube video compilation into Blogify, which uses AI to editorialize video content and make it suitable for long form blogs. It is made to imitate my writing style, the content generated using MY video content and work, so this seems like an entirely appropriate use of AI that shouldn’t be blocked, demoted, or banned, as it is all still essentially me — using the very AUTOMATION tools that are the topic of my channel. I understand Medium wants to eliminate spam writing, and I agree wholeheartedly, some of it is… just awful. However, I don’t feel AI generated stories like this qualify. What say you, dear audience?

Thank you for reading!

Until next time….

Onward and Upward Everybody!

-Chris

Automated Income Lifesyle w/ C.W. Morton

I'm just a regular guy who automates everything I possibly can. ⭐ SUPPORT THIS CHANNEL…www.youtube.com

#medium #3dprinting #homebusiness #online #niche #nichemarketing #nicheproduct #smallbusiness