In 2017, I started a 3d printing business from home, and by 2020, I had scaled it to over six figures.

Then Covid hit and my income fell a little bit. So I decided to automate most of the business.

And I’ve now automated it to the point where I only have to spend about 2-4 hours a week on custom jobs at home.

Want to learn how I did it?

Join me on this fantastic printing voyage.

(This blog is available in video form at the end of the post if you would prefer the video).

I’m going to show you how to identify the best product for you to make and sell, as well as giving you some examples of some niches, just to give you an idea springboard.

Necessity is the mother of invention.

When I started this, I was not a 3d printing hobbyist looking for a product that I could sell.

I started from a completely different angle.

And I think that there’s a lot of people out there who are literally at the brink of this angle, but maybe don’t have the money to pay for a 3d designer and think the whole thing is so complex that it stifles their idea.

I wanted to show you how to manifest that idea.

In 2016, there was a newly forming niche that needed cigar molds.

I was starting out in the cannabis industry and we needed a product, and I stumbled onto cannabis cigars made with traditional tobacco cigar molds, and I was just mind blown.

I knew immediately that I wanted to get into this, to kind of master it, and to push that.

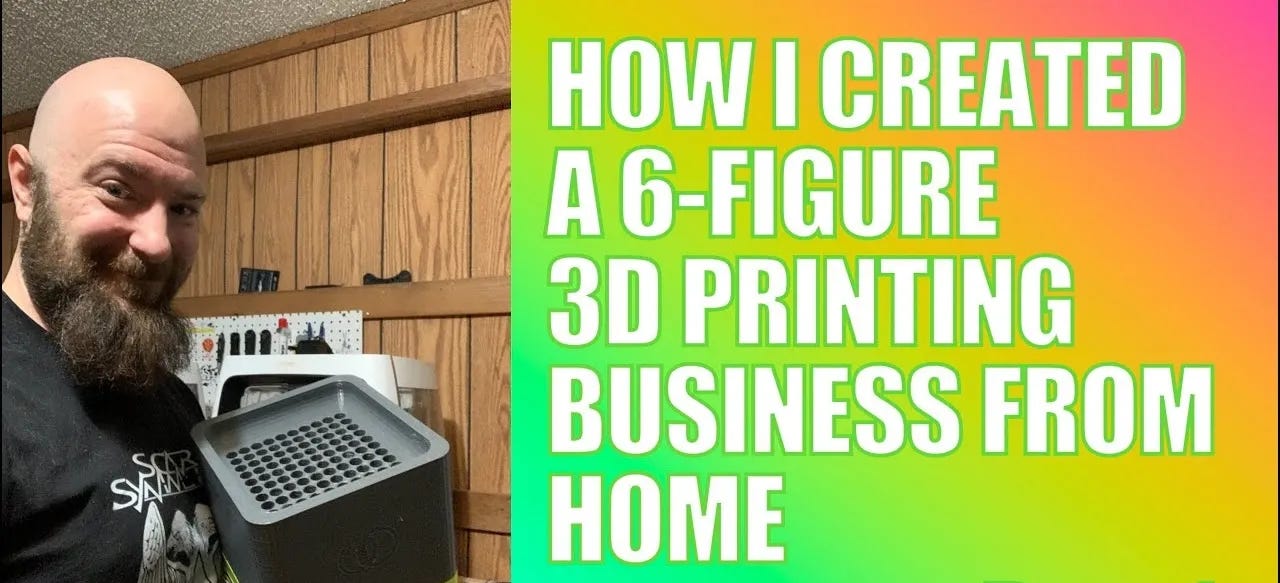

My primary business, Cannagar Tools, is the thing that turned into six figures. It is a brand and a tool set that I created.

And 3D printing happened to be perfect for this particular tool.

All the existing tools at the time were available in very specific sizes, usually for big tobacco cigars, but we needed much smaller sizes.

We needed an array of different shapes and things like that.

I was contacting cigar mold companies, I was finding wooden molds and things I could have and made online in limited quantity, but wood had problems that made it not ideal for this process, and plastic turned out to be great, but it was going to cost me close to ten grand per order to get just one size to test because of their Minimum Order Quantity on custom molds.

So I found a specific niche in which 3D printing applied perfectly and would allow me to create all the sizes that I needed.

And what actually ended up happening to me is everyone around me who was part of that niche wanted my tools.

So I started selling them.

And then after that I launched a website and kind of the rest is history.

My specific example is an industry that had a problem, a particular need, and me finding a way that 3d printing would fulfill that need.

I purchased a 3D printer for myself to make the tools that I needed.

I had zero experience in 3d design, meaning I didn’t know CAD, I didn’t know any of that stuff.

I received my printer and I instantly had a problem.

How do I make something that I want to make?

Can’t I just print and sell the 3d models that I find online on Thingiverse?

No, there are laws against it. Even though those models are freely available, most of them are not commercially available.

Some of them are. You have to read into the licensing.

But for the most part, you’re not going to be able to start a store just freely printing what’s available.

It’s also going to be hard to start up a 3D printing service.

You’re competing with monstrous size businesses.

And unfortunately it’s going to be really hard to get an edge on your competition if you’re just offering 3d printing as a service outside of a very trustworthy word of mouth network.

Not going to say it’s impossible, but that is not what I did.

This is why I recommend going niche.

This will ultimately be what builds your business, what builds your reputation, and later on you can even approach different 3d printing partners, show them the business and the demand for your product, and you can then leverage deals with those businesses to take production off of your hands.

If you want to do that one day, look for a market that has a need, but also has a problem fulfilling that need, then do some research and find out if 3d printing would be a viable option for fulfilling that need.

I cannot stress this enough…Ideally, this will be found in an industry connected to a hobby that you are already passionate about.

The more you can be an authority on something beyond just the printed part, this will make everything so much easier.

If you can find a way to apply 3D printing to something that is already in your life that you are an authority about, you will be able to push this with much less effort.

I had a need, and it turns out that the industry that I wanted to get into also had this need. 3D printing turned out to be not only a viable option, but to really be perfect for what I was trying to accomplish, which was an assortment of different sizes and shapes made to order in any quantity, so that I could empower people to actually research and develop on different products without having to pay these exorbitant minimums to get new sizes and shapes.

I’ve prepackaged a few ideas that you might investigate.

I think these might apply to lots of different people out there.

OEM Replication Car Parts

There are all sorts of different cars out there where parts are really hard to find, or they’re just very, very, expensive.

I’ve got a buddy, a Honda guy, who’s requested that I’ve make several parts for him.

And if you’re out there and you’re a car guy, this might be a perfect niche for you to sniff on and find the right thing for you and run with it.

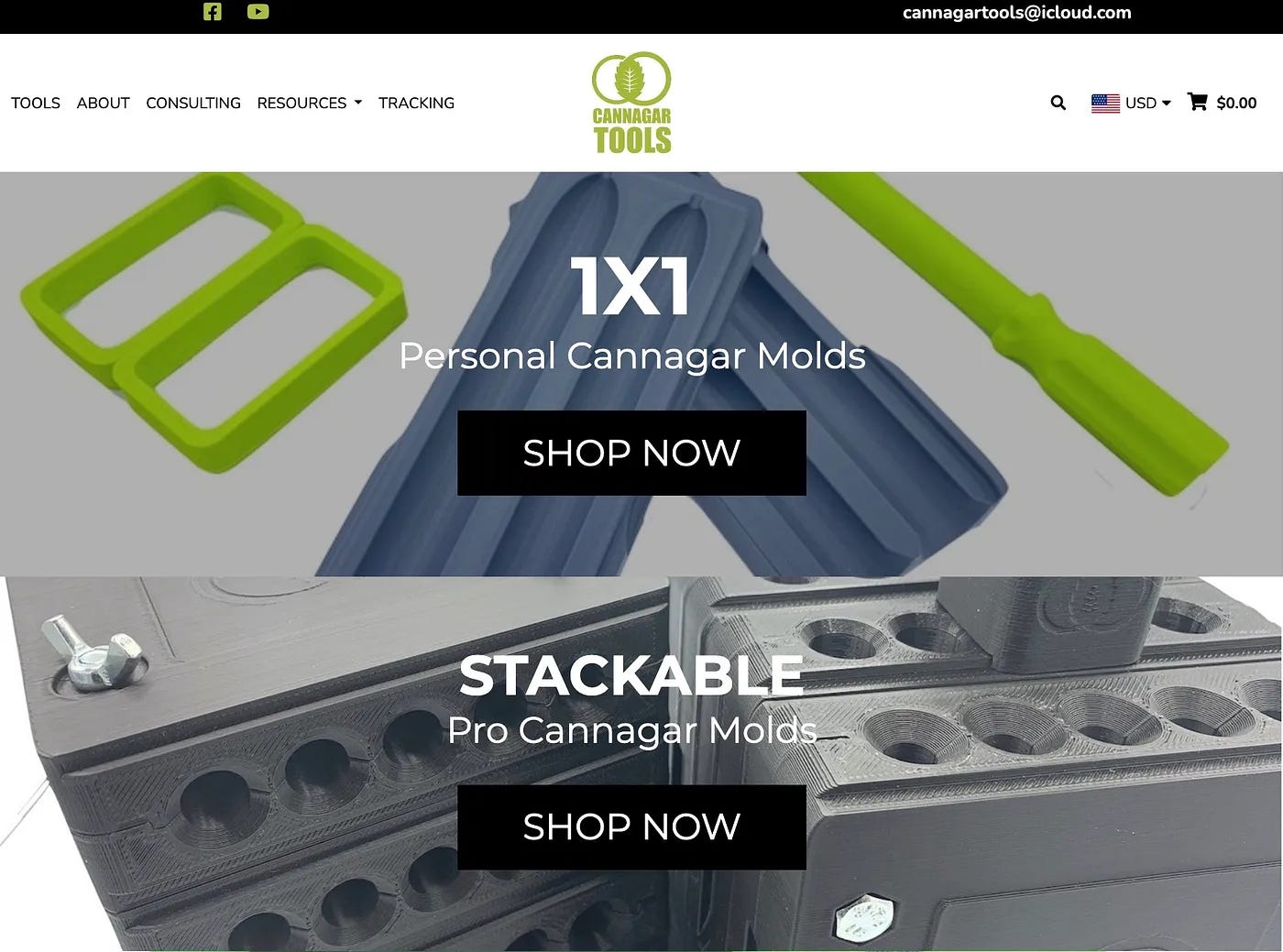

Video Game or VR Accessories

This is another example where if you already have a hobby and you’re very into something, think to yourself, what is it that I want?

What do I need?

Is there something that I could have right now that would either make my experience better, augment or enhance my experience?

You might have the answer to what product you want already, and now you need to make it.

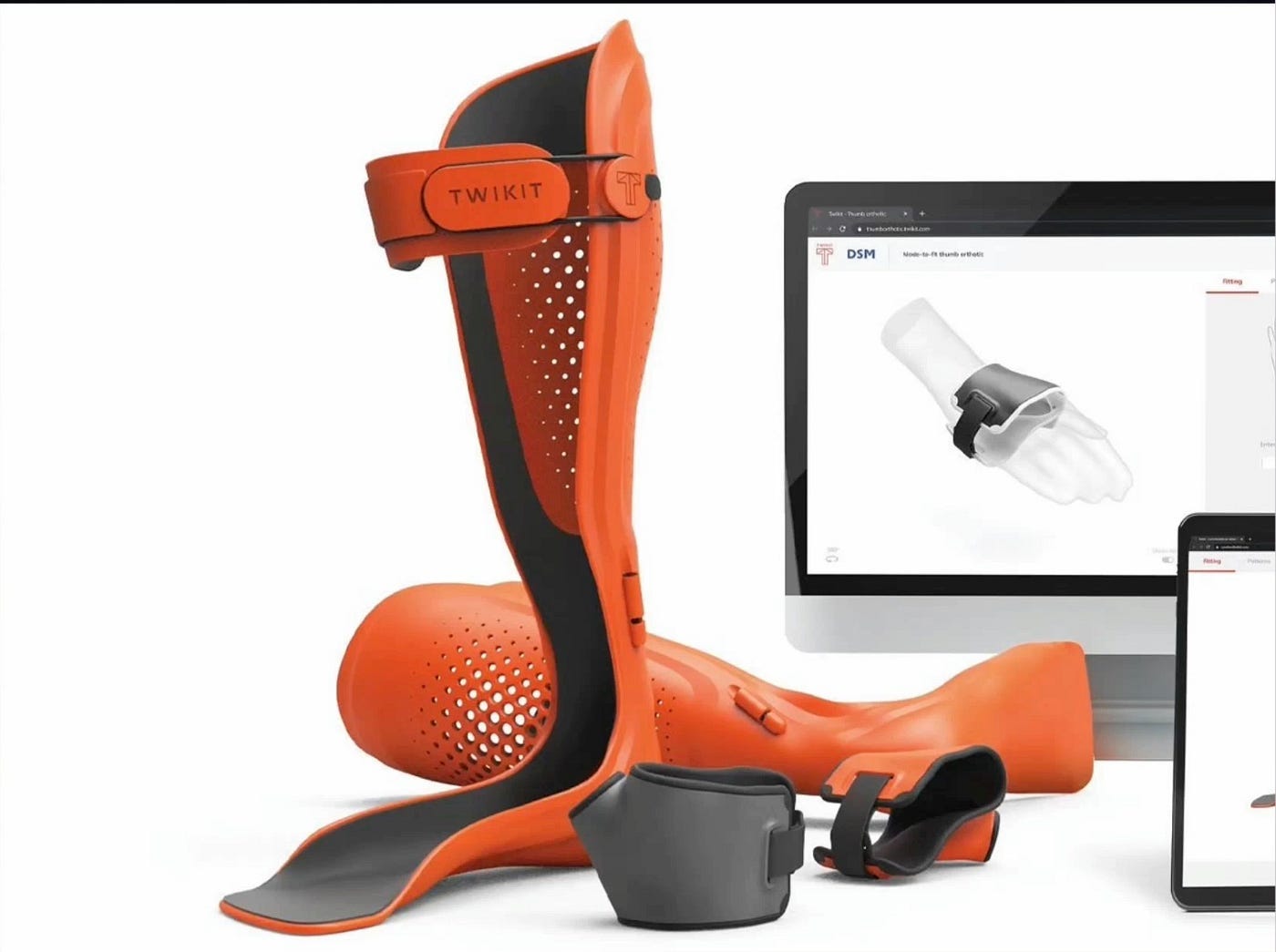

Custom Orthotics / Prosthetics

This is definitely a little bit more advanced, but, I mean, the imagination is your limit here.

There is no limit to the way you can enhance or make more useful through intuitive design and having access to tools that allow you to rapidly prototype and manifest those ideas into reality.

Pet Prosthetics

Certainly it will be true that it’ll be a lot easier to take something to market and actually find a viable way to sell it without the regulatory burdens that you might have with human prosthetics.

And just look at some of these things!

These are both 3d printed examples and they look amazing!

This kind of stuff you can make at home and enhance people’s lives, enhance people’s pets lives really serve a purpose that makes you feel good inside.

There are really endless options, but finding a market where the price you can charge, and the time it takes to produce them pair up, you’re on the winning track.

Here’s the video version of this blog, if you prefer watching over reading :

Thank you for reading!

If you enjoyed this article, here are three ways you can help me out:

Leave an appreciation and a comment if you enjoyed

Until next time….

Onward and Upward Everybody!

-Chris

#3dprinting #3ddesign #unconventionalbusinesses #homebusiness #automation #soleproprietor