Commercial scaling introduces challenges

Scaling and delivering Thai sticks is hard, but not impossible.

The primary challenge lies in the fact that Thai sticks require a real precision, care, patience, and method, and those who make them are usually committed artists, you can’t just grab a random employee and assign them to make Thai sticks. It is a very specialized labor.

The maker must be engaged, enthusiastic, and knowledgable, or the product will flop.

When using wet leaves and softer squishy buds, the potential for mold is far greater. Controlling this becomes a huge challenge at every stage.

When I stumbled on Liera, I could immediately tell they were using molds of some kind because of the perfect shape, and then I looked online and found cigar molds to order and test.

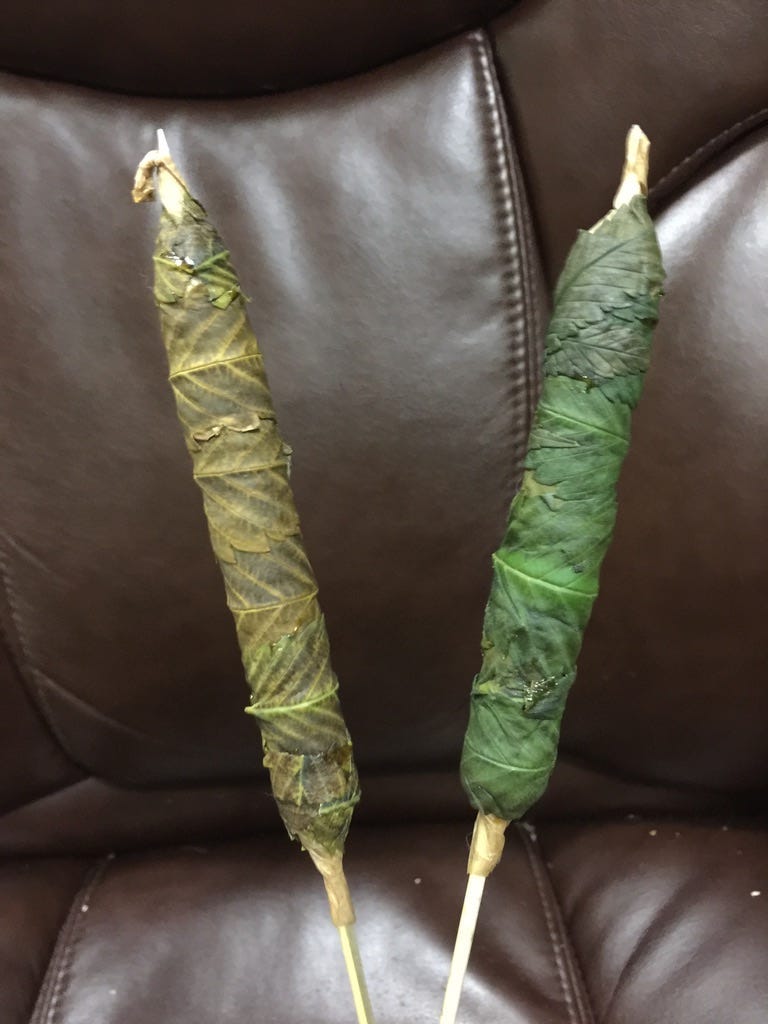

Here are the results of that test:

They were far from perfect, but the form-factor is what I was going for — the perfectly cylindrical stogie.

The problem: I didn’t get to smoke those. Mold destroyed them before they were done. This happened a few times, until I finally nailed a process with a dehumidifier that worked in my small space.

Then I received a reply from the Craiglist post I had made showing off my better looking versions. I was looking for a cannabis company who would fund my development and scaling.

I knew I was going to need to have at least one ready for consumption, so instead of using wet buds, I used fully cured buds instead.

The difference was night/day.

I don’t take credit for that development at all, others were doing this before I attempted it and I was holding out, trying to do the thai-stick thing for tradition sake (really the marketing of “tradition”), but eventually reality and practicality caught up with me and not only was this method going to taste much better, issues with mold were gone.

Done and done.

I packed my molds with ground cured flower around skewers, left them overnight, took the cores out of the molds, wrapped them with leaves, and then I placed them in a second larger mold to cure the leaves.

5 days later I drove to Deception Pass Washington and stayed the night, waiting to show up the next morning at the offices of EH Farms to show off my product.

In hindsight, the leaves I used looked atrocious, and the process left them a bit lumpy, but at least the company who I was consulting for didn’t know the difference — and with their help and access to copius amounts of material, I was able to develop into a real process on-site over the coming months.

My canna stogies were pretty that day — and novel — something they had never seen before, which was all that mattered.

The Core

Most makers have ultimately switched to this newer cured-bud-solid-core cigar mold based method. On top of eliminating mold concerns and being widely more accessible for unskilled labor to help with, updating the methods to a more modern scalable process with cured buds brought with it several huge benefits:

It simplifies the Thai-stick process and makes it accessible to anyone, while reducing production time significantly through incorporating cigar molds.

This eliminates the painstaking labor of using hemp twine to bind wet buds around a skewer. (In the time it takes to mold 5 Thai sticks with hemp twine, I made 20 solid cores in cigar molds).

Mold issues are mostly eliminated.

The process produces a thick and solid cylindrical body, which burns very slow and truly recreates the smoking experience of a cigar — a long slow burn. A real stogie.

This end product will not “poop” resin onto the lips, as long as the smoke channel created by the skewer leaves enough airflow

The product cannot be “hot boxed”, as the body is completely solid and incapable of becoming soggy with repeated puffing/heat.

The slow burn is a huge selling point.

I take them on all-day events like fishing trips or hiking, and they last the entire day, sometimes multiple days.

In fact, it is entirely possible to smoke-out an entire city bus and still half of your Cannagar remaining!

I did it with Made in Xoalin when I visited Colorado and we went for a ride on a cannabis bus tour with their founder Christopher Wallace Louie.

I had never really smoked with THAT many people before.

Sure, I’ve smoked at concerts, but usually a bunch of people have their own little smoke circles going — it’s not all sharing ONE item.

This was a single smoke passed around a cool 30–40 people, not being hotboxed in the slightest, and leaving everyone smiling. That made my year.

Their Godfather smoked out an entire city bus, and then some.

Xiaolin - Cannabis Products and Lifestyle

Xiaolin is a pioneering creative rolling company dedicated to crafting exceptional cannabis lifestyle products and…www.madeinxiaolin.com

They were one of the first companies I consulted with when this niche was fleshing itself out between 2016–2020, and they have really pushed the Arte into new territory.

On site with them, it didn’t take even two batches of leaves to figure out — I still had work to do. The cores were ready, but my leaf process, needed much R&D.

More on that later…..

The New Method, Step by Step:

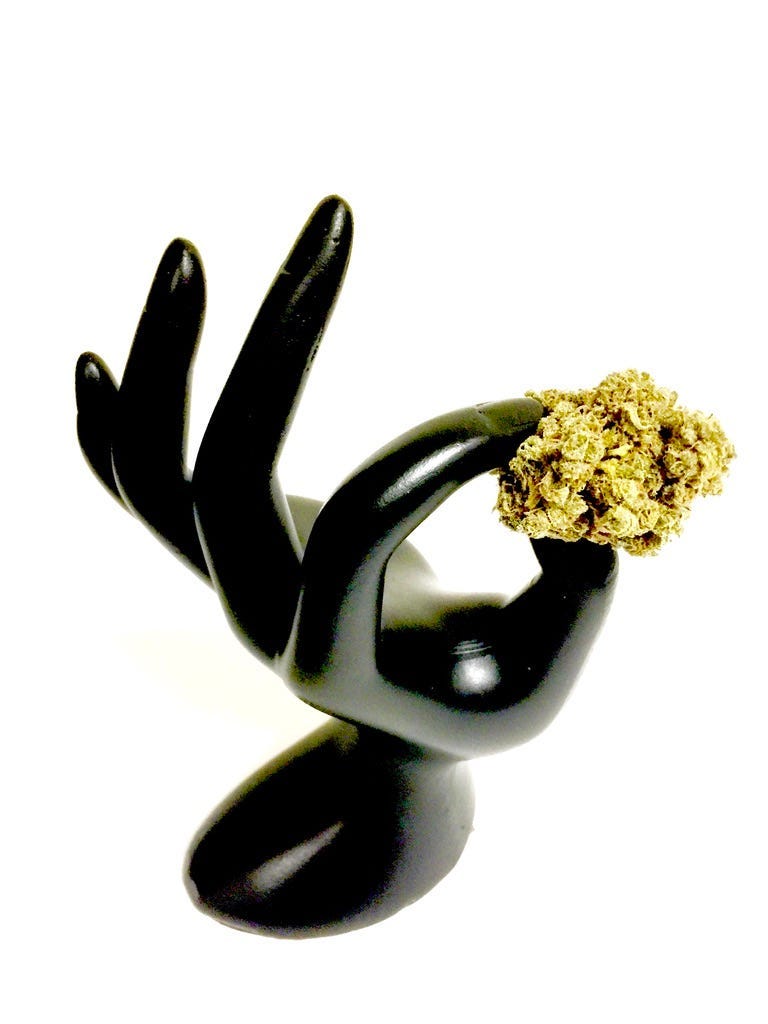

You first need to grind your cannabis flower into soft-easy-to-pack material,

OR

use smaller buds, de-stemming them as best you can.

For best shelf life, little buds well de-stemmed, is the best option.

This is due to what happens when we grind cannabis.

Grinding tears material apart and kickstarts a decomposition process when oils, lipids and waxes are released by crushing the buds. This is why joints left out in the open tend to go stale rather quickly. Staleness is decomposition kicking in, and the first thing to go are those precious terpenes that make the flavors we love!

There are ways to overcome this such as vacuum packing or nitrogen packing, but for most home and artisan Cannagar makers, nitrogen packing is not feasible.

It’s really a question of when do you plan to consume it?

For my own personal Cannagars intended to be consumed within 1–2 weeks of making them, I choose ground flower and prefer the results. However, that cannabis cigar will go stale after 2–3 weeks, and no longer tastes very good.

If I use quality concentrates like Rosin that become hash over time, sometimes the flavor of the Rosin can mask the staleness just enough to pass, but for a real scaled commercial operation — unless you are going to nitrogen pack — I do not recommend doing this.

All the cannabis cigars that I make that are intended for sitting on shelves are made with little buds, de-stemmed as best I can, packed without grinding them up. They last up to 6 months before the flavor starts to slip a little, and the reason is that the decomposition is partially slowed by NOT grinding the material.

Not many of the younger generation know this but — growing up in Texas 25 years ago, the best weed we had was either “hyrdo” or “regs”, and regs — if you were lucky to get the “brick weed”, it was always more dank and fresh than non-bricked regs.

Why?

Compressing weed, without grinding it, seems to preserve it fairly well. Strange, but true.

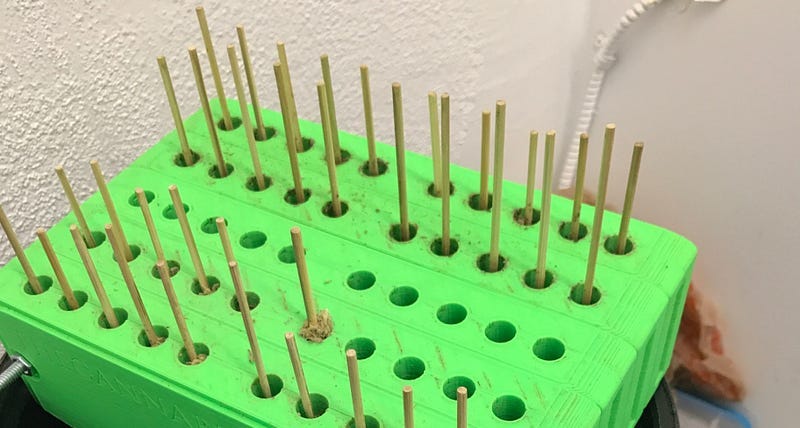

Next, once you have your tools ready and your flower prepped, you will need skewers or metal rods to create a smoke channel.

Place the skewers into the molds one skewer at a time, only need one in the mold that you are packing.

Don’t place all of them into the molds at the beginning, or your hand will have no space!

Drop your flower into the mold slot and use the included BudDriver to pack the buds into your mold.

The BudDriver has a hole passing through it to allow the skewer to pass through while it packs the bud around the skewer.

Only pack a little at a time to avoid creating gaps in the flower body.

This is an art and takes a bit of practice.

You can pack the mold all the way to the end, OR fill it only to the weight/length that you desire.

You need to leave the flower bodies to set shape overnight.

This will minimize stretching and swelling.

It takes about 24 hours for most strains to set into stable shape.

Then you will remove the bolts from your molds and separate the halves of the mold. There are finger grip recesses on the sides of the molds that will allow you to separate the halves rather easily. Now it’s time to dis-lodge your flower cores!

If you are having trouble removing flower cores, there are three things to remember :

* NEVER pull up on the skewers, this will rip flower cores faster than anything else.

* NEVER pull from either end, and this tends to cause the same.

* NEVER use any kind of prying tool, that will also cause damage

Instead, put all fingers along one side of the core, and pull towards you, this will pop them out 99% of the time no matter how sticky your buds are

Simple leverage, easy peasy.

Wrapping

Next up, you need to decide what you are using to wrap, and how you are wrapping your Cannagar.

When many companies start to understand the complexity and labor behind leaf-curing, they elect to use blunt wraps or hemp paper, which can be applied with a little bit of water.

This wrapping process is somewhat like paper mache, and I have a good video showing the process here:

If you use a dual-gauge process that keeps the bodies firm and form-factor perfect, the end result of hemp-wrapped Cannagars look like this:

A dual-gauge process just means you use two different sized molds to make your Cannagar.

The first, to pack your flower bodies, and the second — a slightly larger gauge, to place your wrapped and finished Cannagars in, for the final cure while the papers dry (or your leaves and concentrates).

The more luxurious Cannagar makers and those passionate about the leaf wrapped appearance will opt to use Cannabis or Hemp leaves with cannabis concentrates as glue.

The end result of that process, is more like this:

The leaf-wrapped cannabis cigar is a fairly labor intensive process than many choose to opt out of, both because of the monumental amount of dedication it takes, and the significant increase to the base cost of the item by using concentrates as the glue that seals the leaves.

The process involves curing the leaves, then knowing how to handle them during the entire process.

Leaves can be cured directly on the molded flower body, but this can cause different problems and is very inefficient and needlessly difficult to manage.

I eventually developed a process to create pre-cured leaves, no longer relying on weeks of drying time which was ultimate not doing anything to the chlorophyll anyway.

Leaves were the last and final frontier of nailing this product for a wider audience and I spent from 2016–2019 testing many different methods until I finally landed on the process that I am using today, and will continue to use forever.

Click here to Continue to Part 3 of this story series…. (To Be Continued)

Thank you for reading!

Until next time….

Onward and Upward Everybody!

-Chris

CANNAGAR SCHOOL

Tips and Process for making Cannagars.www.youtube.com

Cannagar Tools Herbal Craft Molds & Accessories

Tools for making form-factor perfect cannagars!cannagartools.com

#cannabis #cannagar #cannabiscigar #stogie #cigars #retail #process